Steve_Karl

Hero Member

- Messages

- 1,717

Hey there,

I got the tuners installed a few days ago, and did a first string-up test this morning.

Played it for a while and all is good.

Nut is very tolerable right out of the box!

All hi-rez photos here: https://photos.app.goo.gl/YfpGMD71n1SHPSXQA

I'll just add to this thread as work progresses. It will be slow for me. I've got other things that have deadlines so I'll just work on this during the winter.

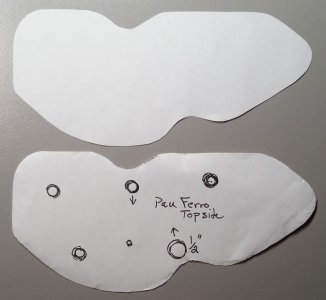

One smaller pic attached.

I got the tuners installed a few days ago, and did a first string-up test this morning.

Played it for a while and all is good.

Nut is very tolerable right out of the box!

All hi-rez photos here: https://photos.app.goo.gl/YfpGMD71n1SHPSXQA

I'll just add to this thread as work progresses. It will be slow for me. I've got other things that have deadlines so I'll just work on this during the winter.

One smaller pic attached.

Attachments

Last edited: