Steve_Karl

Hero Member

- Messages

- 1,726

Hey there,

I've got a problem with the A string either binding at the nut or maybe a bad tuner. The tuners are Schaller Mini Locking.

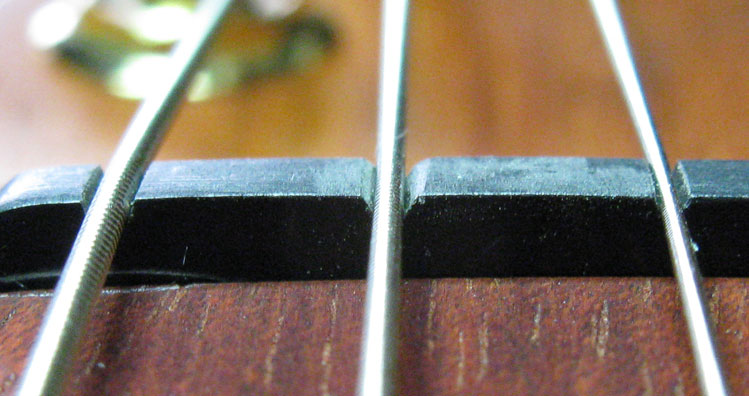

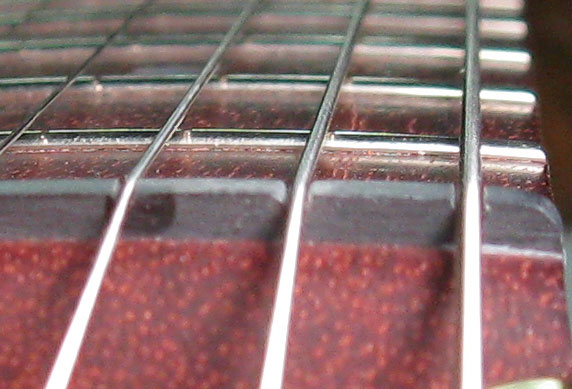

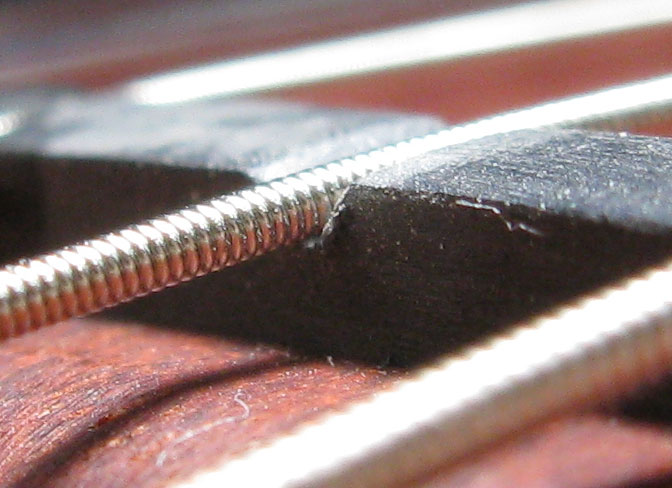

This is on a new build and new neck from W. with W. installed Black TUSQ XL nut.

It will tune up and stay in tune until I dive a bit too far with the Wilki VS-100. No problems with any other strings that I can find as yet, but of course when the A goes sharp after a dive the others don't come back until I retune the A.

When turning the machine head and while watching the pitch of the A on my Peterson VS-1, I can turn the knob about 1/3 or a turn down, before the pitch of the A string changes. I can get the A intune by going below pitch and bringing it up, but when turning the gear down, it always takes from 1/4 to 1/3 or a turn for the pitch to move. SO, after removing some material from the nut, this is why I'm beginning to suspect the tuner.

Opinions on that possibility are very welcome.

Anyway ...

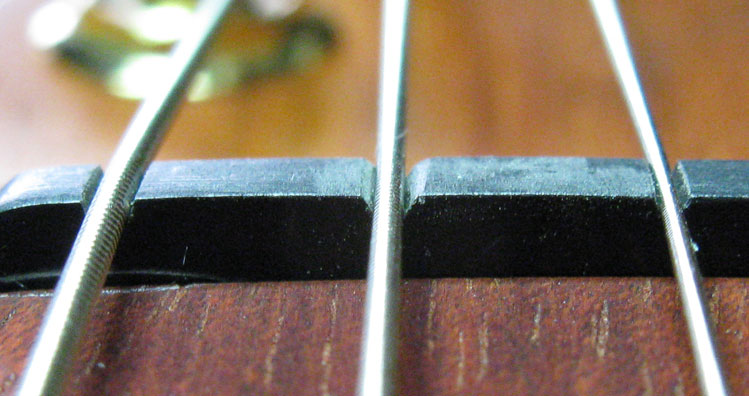

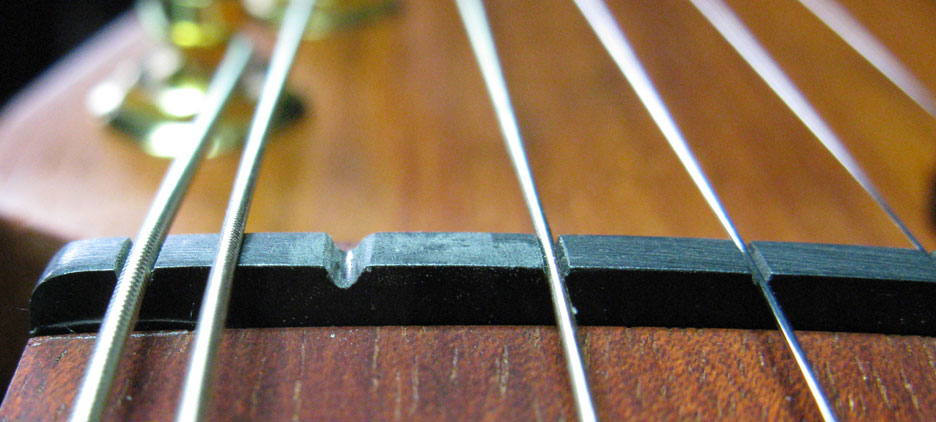

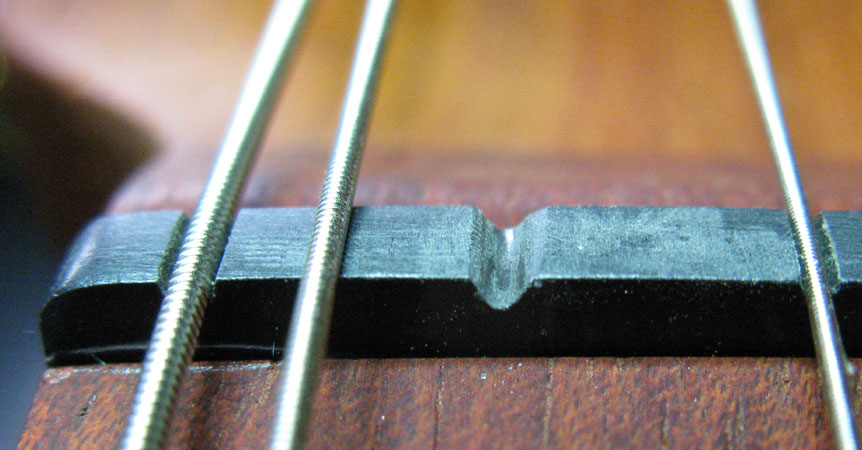

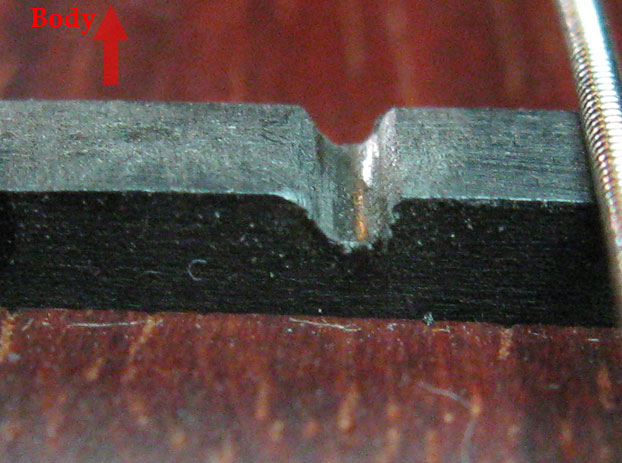

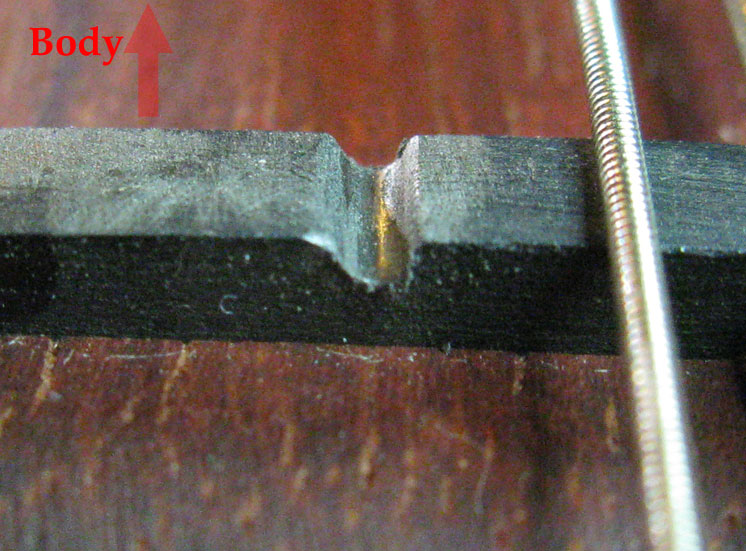

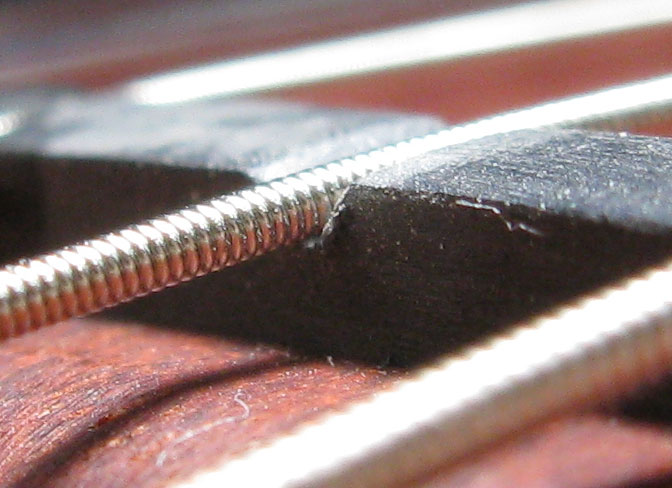

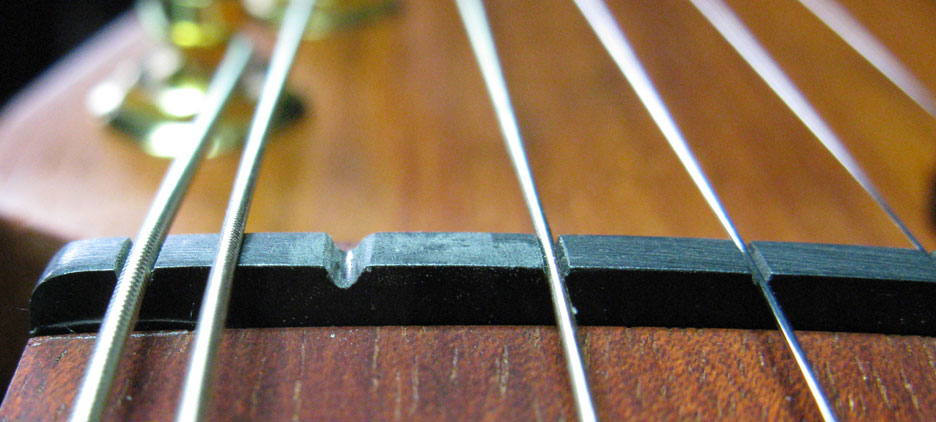

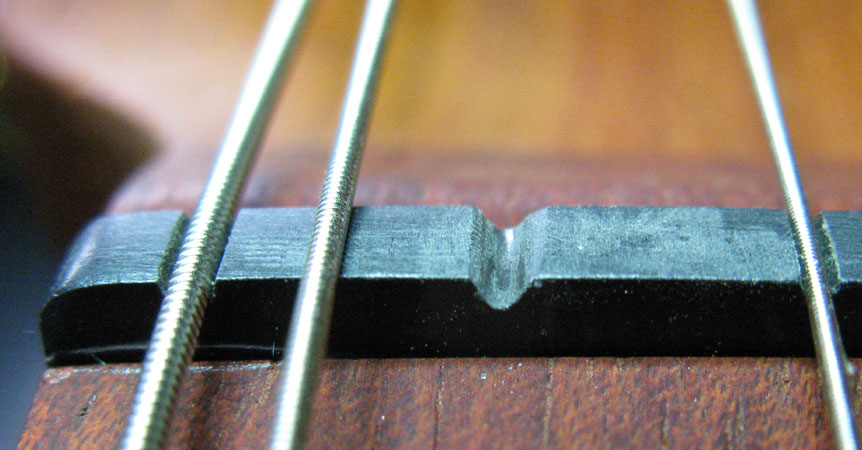

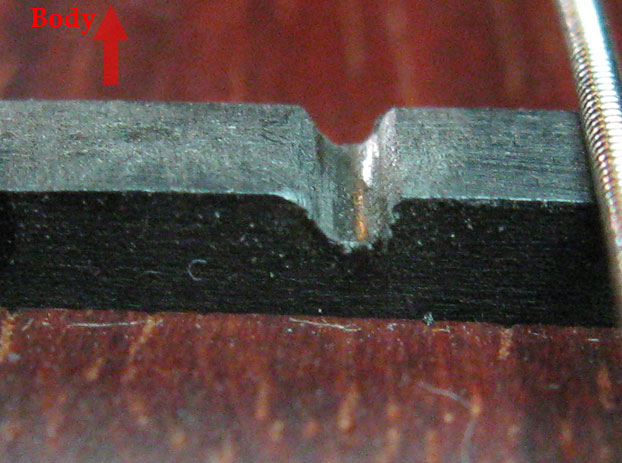

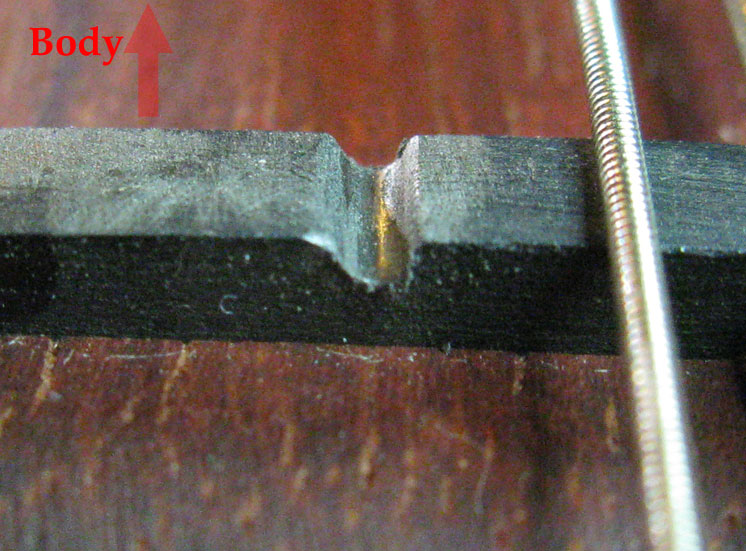

I've removed some material on the high side of the slot, the side closer to the D string, using a very small triangular file and a sliver of emery paper, and I've also dragged a piece of low E string through the slot a few times, back and forth, trying to widen the upper part of the slot. Unfortunately I don't have any nut files.

I also gave it a heavy dose of graphite but that made no difference.

I'm a bit reluctant to continue without some guidance since I really like the way the A string feels ( all of them actually ) and I don't want to make it sit lower than it is, and I'm also not wanting it to go off towards the E string by removing too much from that side of the slot.

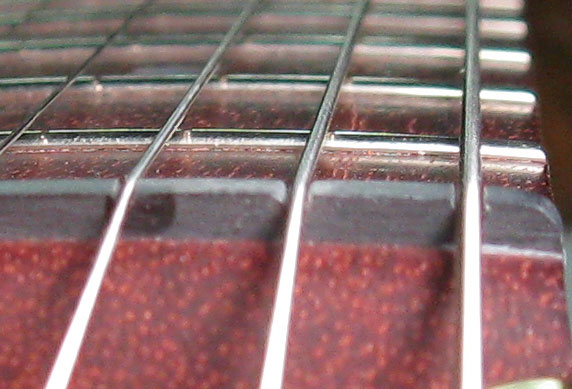

Please have a look at the pics and please advise.

Thank you!

I've got a problem with the A string either binding at the nut or maybe a bad tuner. The tuners are Schaller Mini Locking.

This is on a new build and new neck from W. with W. installed Black TUSQ XL nut.

It will tune up and stay in tune until I dive a bit too far with the Wilki VS-100. No problems with any other strings that I can find as yet, but of course when the A goes sharp after a dive the others don't come back until I retune the A.

When turning the machine head and while watching the pitch of the A on my Peterson VS-1, I can turn the knob about 1/3 or a turn down, before the pitch of the A string changes. I can get the A intune by going below pitch and bringing it up, but when turning the gear down, it always takes from 1/4 to 1/3 or a turn for the pitch to move. SO, after removing some material from the nut, this is why I'm beginning to suspect the tuner.

Opinions on that possibility are very welcome.

Anyway ...

I've removed some material on the high side of the slot, the side closer to the D string, using a very small triangular file and a sliver of emery paper, and I've also dragged a piece of low E string through the slot a few times, back and forth, trying to widen the upper part of the slot. Unfortunately I don't have any nut files.

I also gave it a heavy dose of graphite but that made no difference.

I'm a bit reluctant to continue without some guidance since I really like the way the A string feels ( all of them actually ) and I don't want to make it sit lower than it is, and I'm also not wanting it to go off towards the E string by removing too much from that side of the slot.

Please have a look at the pics and please advise.

Thank you!