kevin_guitars

Junior Member

- Messages

- 75

Showcase "screaming deal" Strat

Alder body

Flame maple top

Somehow I snagged one where the flame top was cheaper than showcase bodies without

*Unfinished

Showcase CBS Strat Neck

Maple Shaft/Maple board

Stainless frets, standard thin profile 10"-16"

I opted to have Warmoth apply a satin tinted nitro to the neck on this one

My buddy and I both are making very no frills, straight to the point, slightly hot rodded Strats. Going for tones like Mayer, or SRV. He's calling his a blues-caster. I'm settled on Penta-caster. We joke that there will be only one scale played on them. I've made some good headway this week on the Strat, while also doing my Z-body build. Many late nights after work in the garage.

First up is to dye the top black and sand it back to sink into the flame. For this I used undiluted Rit Dye

Alder body

Flame maple top

Somehow I snagged one where the flame top was cheaper than showcase bodies without

*Unfinished

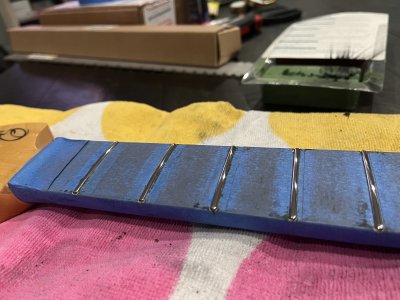

Showcase CBS Strat Neck

Maple Shaft/Maple board

Stainless frets, standard thin profile 10"-16"

I opted to have Warmoth apply a satin tinted nitro to the neck on this one

My buddy and I both are making very no frills, straight to the point, slightly hot rodded Strats. Going for tones like Mayer, or SRV. He's calling his a blues-caster. I'm settled on Penta-caster. We joke that there will be only one scale played on them. I've made some good headway this week on the Strat, while also doing my Z-body build. Many late nights after work in the garage.

First up is to dye the top black and sand it back to sink into the flame. For this I used undiluted Rit Dye