Dazkeirle

Junior Member

- Messages

- 192

Hi guys, can I ask a massive favour?

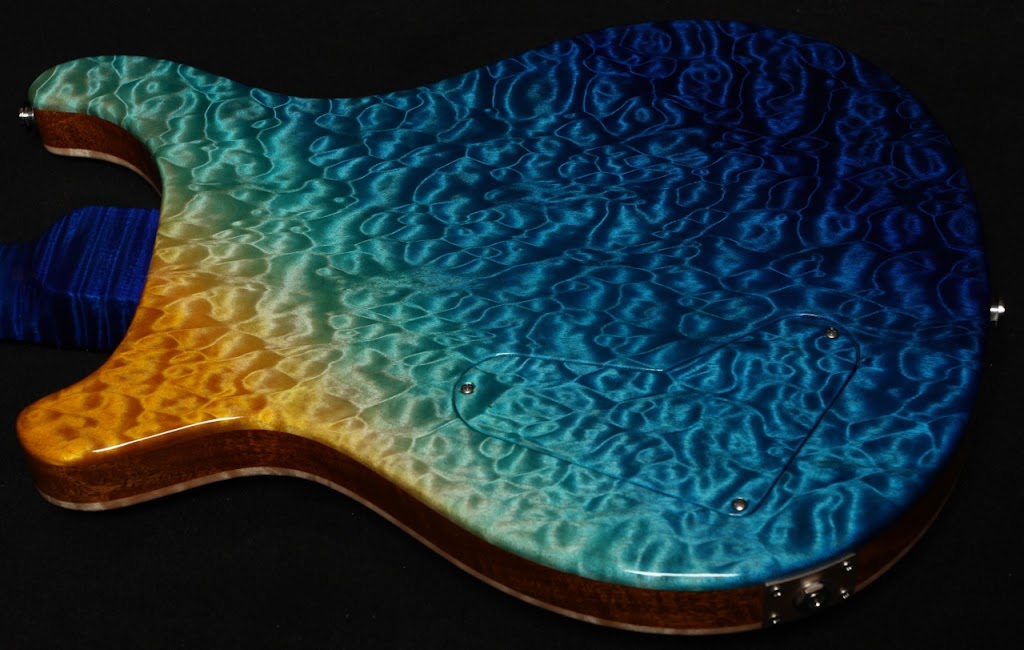

I need a control cover for my soloist but unfortunately my body didn't come with one.

They are an odd size / screw spacing and while warmoth will supply a replacement it means paying for an incredible amount of postage to send from the US to the UK.

Now, I do have a 3D printer and so was wondering if, just temporarily, somebody wouldn't mind doing a scan of their cover on their printer?

From this I'll be able to sketch and print a temporary replacement until I order a new body / neck from Warmoth and add a control cover to that order where it'll get buried in the cost.

I know this is a lot to ask, but if you are bored and fancy helping a brother out, removing 4 screws and hitting scan would save me hours/days of work tracing and wasting trial and error prints.

Many thanks.

I need a control cover for my soloist but unfortunately my body didn't come with one.

They are an odd size / screw spacing and while warmoth will supply a replacement it means paying for an incredible amount of postage to send from the US to the UK.

Now, I do have a 3D printer and so was wondering if, just temporarily, somebody wouldn't mind doing a scan of their cover on their printer?

From this I'll be able to sketch and print a temporary replacement until I order a new body / neck from Warmoth and add a control cover to that order where it'll get buried in the cost.

I know this is a lot to ask, but if you are bored and fancy helping a brother out, removing 4 screws and hitting scan would save me hours/days of work tracing and wasting trial and error prints.

Many thanks.