You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

What's the thickness of a Jazzmaster chambered body?

- Thread starter molul

- Start date

BroccoliRob

Hero Member

- Messages

- 1,112

yo I assume its the same as everything else Big W makes 1.75"

molul

Junior Member

- Messages

- 114

Just to make sure: is 1.75" the full thickness of the body? Or the thickness of the body minus the length of the holes drilled on a chambered body? I'd need to know the latter.

The reason: I ordered a Jazzmaster chambered body and I was told that I could add a battery rout, but after ordering I was told that it was only possible on a rear rout Jazzmaster chambered body (which I can't use for a number of reasons).

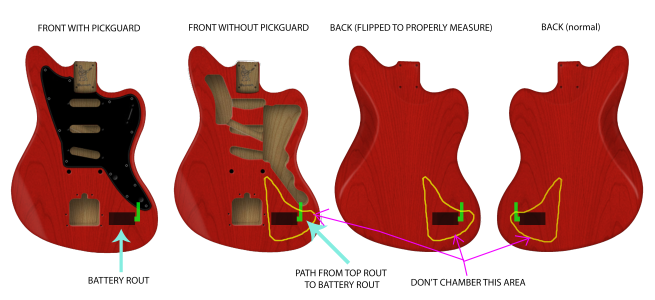

I've been talking to Justin at Warmoth to see if there could be a way to manually adding a battery rout after the body has been chambered, but (if I understood correctly) is not possible because there isn't a program that could do that. The attached picture is where I think it could fit (it would be done in the back of the body), but (although I'm waiting for Warmoth to confirm if it's possible, on Monday I guess) it seems Warmoth couldn't do it, most likely because of how they work (which I respect).

So my intention is ordering the body without the battery rout and asking a local luthier to make this battery rout. He told me he's positive he can, but he'd need to know how deep the holes are, to be sure there wouldn't be any problem.

I've asked Warmoth about it, but I wonder if anyone in the forum already knows, so I can tell the luthier and then confirm Warmoth that I want the chambered body without battery rout.

The reason: I ordered a Jazzmaster chambered body and I was told that I could add a battery rout, but after ordering I was told that it was only possible on a rear rout Jazzmaster chambered body (which I can't use for a number of reasons).

I've been talking to Justin at Warmoth to see if there could be a way to manually adding a battery rout after the body has been chambered, but (if I understood correctly) is not possible because there isn't a program that could do that. The attached picture is where I think it could fit (it would be done in the back of the body), but (although I'm waiting for Warmoth to confirm if it's possible, on Monday I guess) it seems Warmoth couldn't do it, most likely because of how they work (which I respect).

So my intention is ordering the body without the battery rout and asking a local luthier to make this battery rout. He told me he's positive he can, but he'd need to know how deep the holes are, to be sure there wouldn't be any problem.

I've asked Warmoth about it, but I wonder if anyone in the forum already knows, so I can tell the luthier and then confirm Warmoth that I want the chambered body without battery rout.

Attachments

BroccoliRob

Hero Member

- Messages

- 1,112

Ya, top surface to rear surface 1. 75 inches total wood thickness. I think errthing they make is that thick except for the carve tops

molul

Junior Member

- Messages

- 114

BroccoliRob said:Ya, top surface to rear surface 1. 75 inches total wood thickness. I think errthing they make is that thick except for the carve tops

Thanks! And do you know the depth of the chambering?

Oh! Did you do this on any of your guitars maybe? Thanks as well, by the wayRick said:you Won’t have a problem.

I'm still a bit bummed that Warmoth won't want to do this in their factory. I told them I would be glad to pay the extra cost, and I don't think they don't have the tools and talented people to make it, so... I don't, it's a bit weird to me ^_^U

Rick

Epic Member

- Messages

- 6,930

Sure ... I’ve used Drexel tools on chambered bodies, axkoa is on the target. I’ve done it to make cavities larger, and the dremelingvgets covered up with a pick guard or control plate. If the luthier needs to raise the floor of the chamber he just needs to glue in a landing. You’ll be fine

Cagey

Mythical Status

- Messages

- 24,425

molul said:I'm still a bit bummed that Warmoth won't want to do this in their factory. I told them I would be glad to pay the extra cost, and I don't think they don't have the tools and talented people to make it, so... I don't, it's a bit weird to me ^_^U

Call it "risk mitigation". When it comes to modifications, they seem to feel pretty strongly about having done something before. If you or I were to start cutting/drilling/routing on a body and something goes wrong, then it's on us and we have to buy another body. If they do it and get surprised, they have to manufacture another body, hopefully identical to the one they just wrecked (which may not be entirely possible due to unique choice woods).

molul

Junior Member

- Messages

- 114

Axkoa said:I mean, if the chamber is there surely you won't have much problem if you do cut into the chambers? The battery box would cover the chamber openings right?

Yes, exactly.

Rick said:Sure ... I’ve used Drexel tools on chambered bodies, axkoa is on the target. I’ve done it to make cavities larger, and the dremelingvgets covered up with a pick guard or control plate. If the luthier needs to raise the floor of the chamber he just needs to glue in a landing. You’ll be fine

I see. Thank you!

Cagey said:molul said:I'm still a bit bummed that Warmoth won't want to do this in their factory. I told them I would be glad to pay the extra cost, and I don't think they don't have the tools and talented people to make it, so... I don't, it's a bit weird to me ^_^U

Call it "risk mitigation". When it comes to modifications, they seem to feel pretty strongly about having done something before. If you or I were to start cutting/drilling/routing on a body and something goes wrong, then it's on us and we have to buy another body. If they do it and get surprised, they have to manufacture another body, hopefully identical to the one they just wrecked (which may not be entirely possible due to unique choice woods).

I understand, yes.

Well, I guess the stratmaster project is still on! Thank you very much everyone

stratamania

Mythical Status

- Messages

- 12,019

Another possible alternative to a battery box would be to use a Fishman Universal Battery Pack, mounted into the pickguard. All that would be needed to mount it would be to drill a 1/2" hole in the pickguard.

https://www.fishman.com/products/series/fluence/universal-rechargeable-battery-pack/

https://www.fishman.com/wp-content/uploads/2016/07/Fluence-Battery-Pack-User-Guide.pdf

No modifications to the body are then needed, no batteries to replace, just recharge it.

https://www.fishman.com/products/series/fluence/universal-rechargeable-battery-pack/

https://www.fishman.com/wp-content/uploads/2016/07/Fluence-Battery-Pack-User-Guide.pdf

No modifications to the body are then needed, no batteries to replace, just recharge it.

BroccoliRob

Hero Member

- Messages

- 1,112

molul said:BroccoliRob said:Ya, top surface to rear surface 1. 75 inches total wood thickness. I think errthing they make is that thick except for the carve tops

Thanks! And do you know the depth of the chambering?

i have no idea, nor any clue if anybody could actually tell you that. Some1 can probably measure the control cavity of their #Jazzmeister for you, but the only way to know the depth of the chambers is to rip or sand off the top of one

Fat Pete

Hero Member

- Messages

- 1,657

FWIW I suspect the cavities are 1.375" deep, but could be 1.5".

This is simply 1.75" -0.125" for the lam top and -0.25" for the back. They could leave just 0.125" at the back too, hence the 1.5", but it seems likely to me that there's a bit more 'meat' there for various reasons.

All based on assumptions and fever dreams, so take it with a pinch of salt.

An actual battery box has it's own 'floor' and surface-mounts, so the cavity depth wouldn't make any difference anyway. Using one would be the safest option.

This is simply 1.75" -0.125" for the lam top and -0.25" for the back. They could leave just 0.125" at the back too, hence the 1.5", but it seems likely to me that there's a bit more 'meat' there for various reasons.

All based on assumptions and fever dreams, so take it with a pinch of salt.

An actual battery box has it's own 'floor' and surface-mounts, so the cavity depth wouldn't make any difference anyway. Using one would be the safest option.

molul

Junior Member

- Messages

- 114

stratamania said:Another possible alternative to a battery box would be to use a Fishman Universal Battery Pack, mounted into the pickguard. All that would be needed to mount it would be to drill a 1/2" hole in the pickguard.

https://www.fishman.com/products/series/fluence/universal-rechargeable-battery-pack/

https://www.fishman.com/wp-content/uploads/2016/07/Fluence-Battery-Pack-User-Guide.pdf

No modifications to the body are then needed, no batteries to replace, just recharge it.

Wow! Never heard of this, and looks quite sexy! My only worry is that all rechargable batteries eventually loose capacity, and that would mean buying a new one and replacing it.

I currently use USB rechargable batteries. I know they'll loose charge capacity sooner or later, but I would only need to buy another one, not having to install anything.

Fat Pete said:FWIW I suspect the cavities are 1.375" deep, but could be 1.5".

This is simply 1.75" -0.125" for the lam top and -0.25" for the back. They could leave just 0.125" at the back too, hence the 1.5", but it seems likely to me that there's a bit more 'meat' there for various reasons.

All based on assumptions and fever dreams, so take it with a pinch of salt.

An actual battery box has it's own 'floor' and surface-mounts, so it the cavity depth wouldn't make any difference anyway. Using one would be the safest option.

I also think the back thickness must be bigger than the top. The top is a laminate to cover the holes, but AFAIK, the back of the guitar remains the same after drilling, so I'm guessing it must be thicker.

Similar threads

- Replies

- 9

- Views

- 430

- Replies

- 5

- Views

- 233

- Replies

- 3

- Views

- 342