jackthehack

Epic Member

- Messages

- 5,630

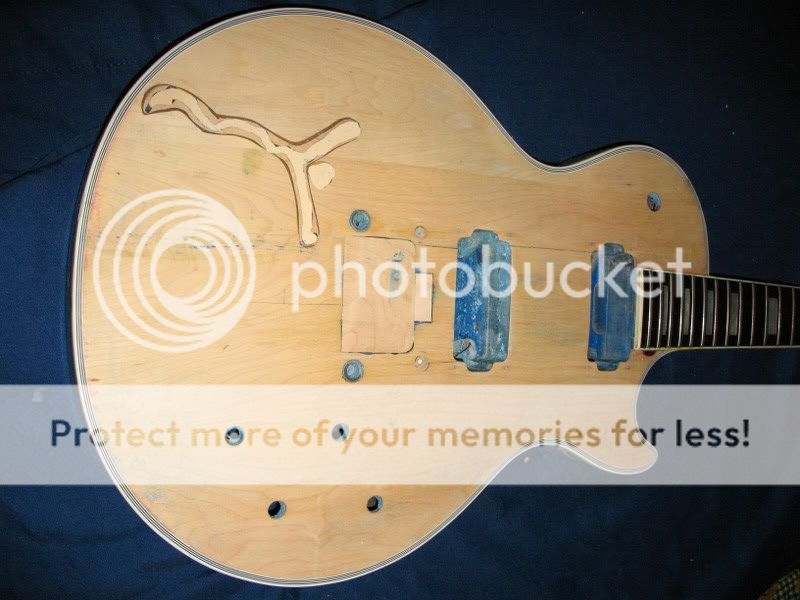

What's the best advice of those on this board for stripping the poly finish from the top of a LP body? Body is mahoghany with a flame maple laminate top, has a top binding and a botched sunburst....

-CB- said:Nice job...

So if this Eldorado stripper is waterbased does that mean it can be shipped by air?

Tonar8353 said:So if this Eldorado stripper is waterbased does that mean it can be shipped by air?

Yes it can be shipped by Air. Call Eldorado at 800-531-1088 and find the closest distributor to you and have them ship it. The list price on it is $61.88 per gallon so you have an idea of the price range.