sea-monster

Newbie

- Messages

- 2

So I'm thinking about building a custom body with a Warmoth neck and have a question about the amount of body wood needed to make for a secure neck joint. I like the way it looks when there's not much overlap of the fretboard onto the body of a Rickenbacker 330.

Rickenbackers have set necks, I believe, and I'm curious to know if I can create a similar look with a bolt on neck. Fender guitars, which use bolt on necks, look to have a bit more body wood bracing the sides of the neck.

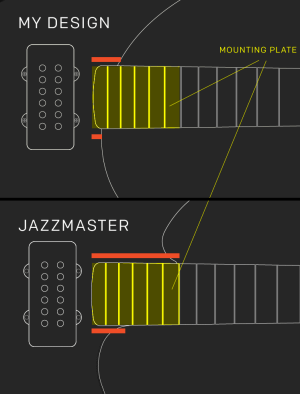

I've made an image below to show the difference between a Fender Jazzmaster and the design I'm working on. As you can see, the custom design on top has far less body wood touching the sides than the Jazzmaster. They both would have the same surface area on the back for the neck mounting plate.

Does anyone have a good idea if I could do such a thing with a bolt on neck?

Extra Credit: If it *is* secure enough, could I make a contoured heel on the body as well?

Rickenbackers have set necks, I believe, and I'm curious to know if I can create a similar look with a bolt on neck. Fender guitars, which use bolt on necks, look to have a bit more body wood bracing the sides of the neck.

I've made an image below to show the difference between a Fender Jazzmaster and the design I'm working on. As you can see, the custom design on top has far less body wood touching the sides than the Jazzmaster. They both would have the same surface area on the back for the neck mounting plate.

Does anyone have a good idea if I could do such a thing with a bolt on neck?

Extra Credit: If it *is* secure enough, could I make a contoured heel on the body as well?