Sponger D.

Newbie

- Messages

- 9

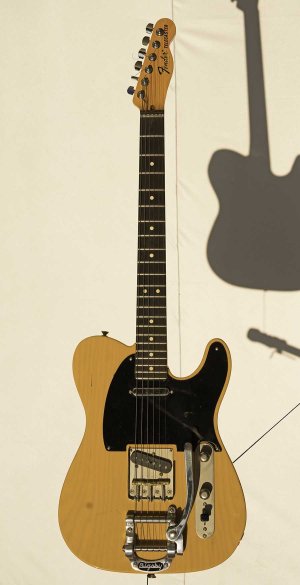

Just completed a VERY nice Warmoth neck (Tele vintage/modern, LSR roller nut, maple, dark ebony fretboard, 6130 low frets, Fender locking staggered chrome tuners). This connected to a Fender branded swamp ash Butterscotch Blonde 6lb 4oz body off eBay. I installed B5 Bigsby, Callaham Bigsby string shaft and roller, and Callaham compensated bridge assembly for Bigsby which I modified. Lindy Fralin pups. So I wanted to do neck (masked off fretboard) vintage amber. After doing bunches of research, started with shellac and added amber tint- took forever and didn't like results. So I got StewMac Colortone sprays: nitro sanding sealer, nitro vintage amber, and nitro clear gloss. Seemed OK. Took off masking tape and went to remove goo from tape with denatured alcohol and the finish came off like it was lipstick. W T F ! ! ! ! ! I have a lot of StewMac stuff- pretty good. I double checked on a piece of poplar board going sanding sealer nitro spray>grain filler X 2>sanding sealer nitro spray X2>vintage amber nitro X3>gloss nitro X3>ample time between all coats. Same thing. F'ing joke. So much wasted time and money. To do the neck right, I will have to disassemble, strip and start over- no way. So now it has a "used and abused" look- fine with me. And I didn't have to pay extra!

How bout surfboard resin over some sort of serious clear primer? I know that s**t WORKS! I'm done with tinkering. I have another maple neck coming from Warmoth and want to do vintage amber gloss. HELP!!!

BTW, I know there are a lot of variables in this art. But without changing anything on the body, I swaped to this neck from another Warmoth neck, and the change was unbelieveable. Pushes my playing (such as it is) to a whole new level. Never had a guitar anything like it- synergy accidental? I don't care- luv it!!!

How bout surfboard resin over some sort of serious clear primer? I know that s**t WORKS! I'm done with tinkering. I have another maple neck coming from Warmoth and want to do vintage amber gloss. HELP!!!

BTW, I know there are a lot of variables in this art. But without changing anything on the body, I swaped to this neck from another Warmoth neck, and the change was unbelieveable. Pushes my playing (such as it is) to a whole new level. Never had a guitar anything like it- synergy accidental? I don't care- luv it!!!