gibby400

Newbie

- Messages

- 1

Hi all, long time lurker here, only just realised I had an account!

I ordered a custom neck in December 2025 and finally had time this weekend to install the hardware. When fitting my FU-Tone brass R2 nut, I found it won’t sit square on the nut shelf, it ends up slightly misaligned.

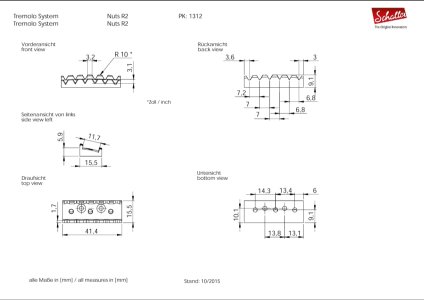

I measured the nut and it looks basically on spec, so I moved on to the Warmoth nut shelf and the mounting holes. With the usual Floyd button-head bolts (with the grip washers) there’s minimal lateral adjustment available. With cap-head M4 bolts I can shift it a fraction more of a millimetre, but the nut still doesn’t sit evenly on the shelf, and I’m hesitant to torque it down against wenge when the contact/pressure looks uneven. Adding M4 washers to even pressure distribution reduces the lateral movement again.

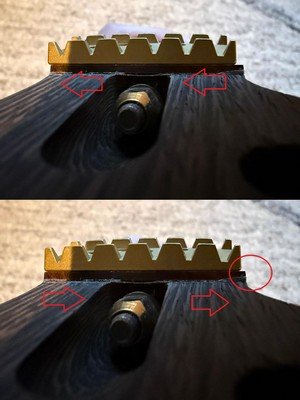

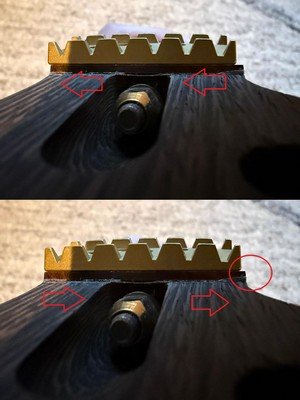

Here’s a photo showing the limits of adjustment I’m getting with cap head M4 and no washer:

I’ve also attached some caliper photos with the measurements:

I’ve contacted Spike at Warmoth and I’m waiting to hear back. In the meantime, I’d really appreciate any input:

Has anyone had any similar alignment issue like this on a Warmoth neck? If so, what was the outcome (plug/redrill, replacement, something else)?

How has Warmoth been more recently - are their necks generally consistent, or are hardware fitment issues becoming more common?

I’m in the UK, so I’m also trying to get a feel for the practical side (turnaround, shipping, duty/VAT if it needs to go back).

I’ll update the thread once I hear back from Warmoth.

I ordered a custom neck in December 2025 and finally had time this weekend to install the hardware. When fitting my FU-Tone brass R2 nut, I found it won’t sit square on the nut shelf, it ends up slightly misaligned.

I measured the nut and it looks basically on spec, so I moved on to the Warmoth nut shelf and the mounting holes. With the usual Floyd button-head bolts (with the grip washers) there’s minimal lateral adjustment available. With cap-head M4 bolts I can shift it a fraction more of a millimetre, but the nut still doesn’t sit evenly on the shelf, and I’m hesitant to torque it down against wenge when the contact/pressure looks uneven. Adding M4 washers to even pressure distribution reduces the lateral movement again.

Here’s a photo showing the limits of adjustment I’m getting with cap head M4 and no washer:

I’ve also attached some caliper photos with the measurements:

I’ve contacted Spike at Warmoth and I’m waiting to hear back. In the meantime, I’d really appreciate any input:

Has anyone had any similar alignment issue like this on a Warmoth neck? If so, what was the outcome (plug/redrill, replacement, something else)?

How has Warmoth been more recently - are their necks generally consistent, or are hardware fitment issues becoming more common?

I’m in the UK, so I’m also trying to get a feel for the practical side (turnaround, shipping, duty/VAT if it needs to go back).

I’ll update the thread once I hear back from Warmoth.