AlternateNosePicking

Junior Member

- Messages

- 29

rgand said:It is close and today I'm going to see about swapping it with the push switch below it. If that doesn't work, I'll have to relocate it completely.AlternateNosePicking said:Makes sense. That Vol knob looks extremely close to the bridge. I'd be interested to know the best way to route such a path while preserving the finish. Easier to do prior to finishing the body.

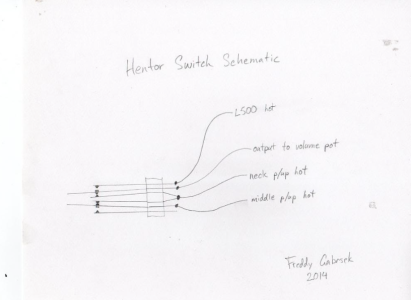

I think the swap you propose makes more sense. I like the idea of the selector switching being where its located on the Hentor, simply because its easier to look down and see the current position. I often watch people play through solos, and their hand frequently flashes down to the selector to change it. I think I would have a difficult time nailing that move. My PRS has a rotary switch to change pickups, which is practically impossible to do quickly.

rgand said:Last time I routed a finished body, I used a drill press with a wood drill that scores around the cut cleanly. Not one of those flat ones, more like a hand auger bit in the photo below but without the screw threads on the center guide or the square shank. It didn't chip or anything but I didn't have a router then. Not sure which way is best if I do it with this one. Probably just careful, slow cutting with a router is best.

Yeah, new router bit is a small price to pay for a clean cut. I have a router and a router table, though I think the table will be fairly useless. I may try to build a jig to accommodate a straight route. At least that way, I can test the route several times before cutting the guitar. I can envision myself royally screwing that up, and even if it was hidden by the pick guard, it would forever annoy me.

By the way, any idea what the lead time usually is on custom Warmoth parts? I figure I need to buy the Bill and Becky L500 first. I've read that their backorder delays are the stuff of legend.