The_GuitAar

Junior Member

- Messages

- 34

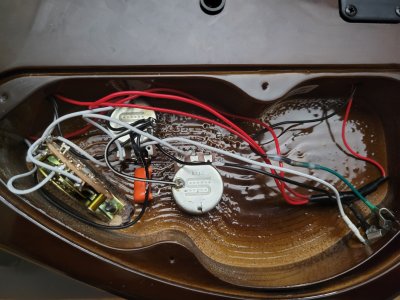

Just got the body and neck today and started to build!

And... So many problems. The biggest one currently being that the 5 way selector switch doesn't work with the body.

The switch's depth is too deep and sticks out from the cavity, and blades switch range is too wide so bridge and neck only options aren't selectable.

Any more experienced guys have any ideas? Not sure what other switches I can pick up (or how to wire them. Was hoping for a drop in with emg... Nope)

Edit: dropped a cool 100$ at Amazon to pick up entirely new pots, switches, solder wire etc. EMG pots are 25k. Not 250k, 25k. Going to have to break out the soldering iron this/next weekend to get this all squared away. First build, already regrets from lack of knowledge.

Oh well, live and learn.

And... So many problems. The biggest one currently being that the 5 way selector switch doesn't work with the body.

The switch's depth is too deep and sticks out from the cavity, and blades switch range is too wide so bridge and neck only options aren't selectable.

Any more experienced guys have any ideas? Not sure what other switches I can pick up (or how to wire them. Was hoping for a drop in with emg... Nope)

Edit: dropped a cool 100$ at Amazon to pick up entirely new pots, switches, solder wire etc. EMG pots are 25k. Not 250k, 25k. Going to have to break out the soldering iron this/next weekend to get this all squared away. First build, already regrets from lack of knowledge.

Oh well, live and learn.