mayfly

Epic Member

- Messages

- 8,716

Good evening gentlepeople,

A while ago my buddy Bill, having played some of the guitars that I made, approached me about making a telecaster for him. Bill is a semi-pro player with a lot of skill. His main two guitars are a fender 'Nashville' telecaster, and a Fender 52 re-issue tele. His faviourite is the 52 (because of, among other things, how it sounds), but he has grown fond of the bender and the extra pickup in the Nashville.

So - we got together and hatched a plan to bring both guitars together into a single unit. That is, build a Warmoth that sounds and looks like the 52, but with a bender. His plan is to sell the other two once we have this one done and sorted.

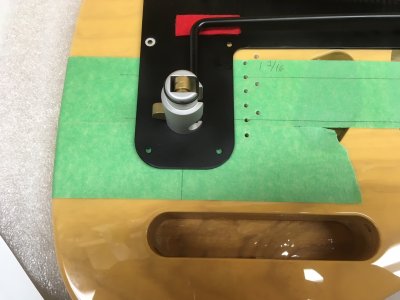

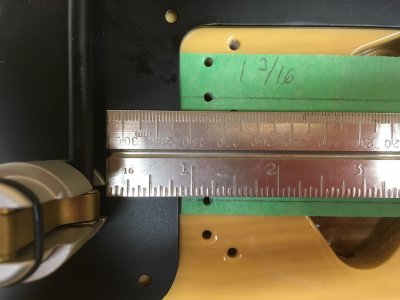

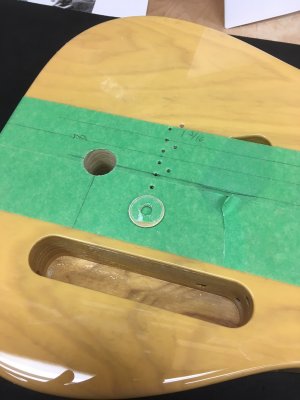

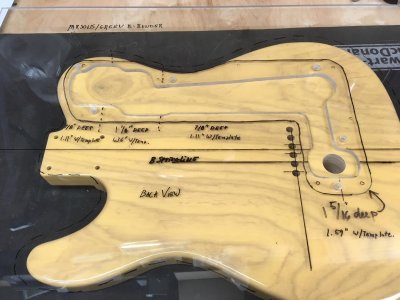

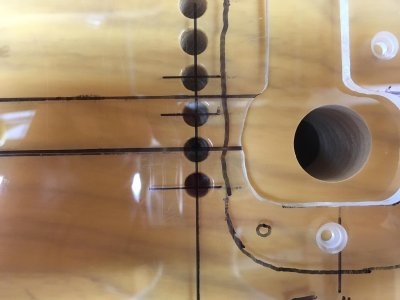

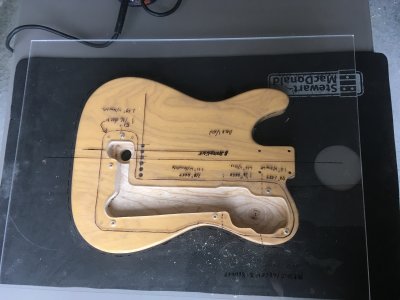

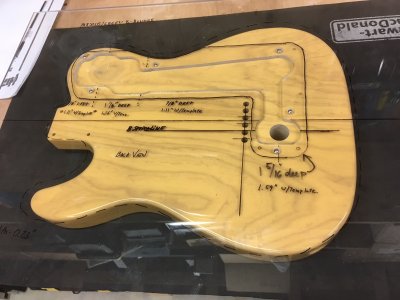

Here's the starting point: a warmoth swamp ash showcase body (re-routed for a strat pickup in the middle) , and a hipshot B-Bender mechanism.

Here's a mockup of what we hope to be a kickass guitar:

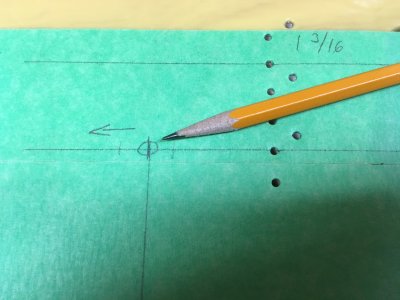

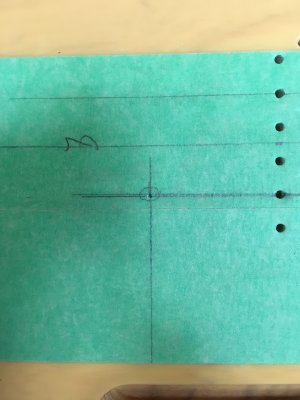

Now I have to confess that this is the first guitar that I've ever built for someone else. Because of that, I'm actually pretty nervous about the prospect! Small stuff that I would normally let pass I can't let happen. My worst fear is to F*ck something up. Because of this, I intend to check and double check everything as I go, as well as document the heck out of the build. If anything it will give Bill a story to tell! :headbang:

A while ago my buddy Bill, having played some of the guitars that I made, approached me about making a telecaster for him. Bill is a semi-pro player with a lot of skill. His main two guitars are a fender 'Nashville' telecaster, and a Fender 52 re-issue tele. His faviourite is the 52 (because of, among other things, how it sounds), but he has grown fond of the bender and the extra pickup in the Nashville.

So - we got together and hatched a plan to bring both guitars together into a single unit. That is, build a Warmoth that sounds and looks like the 52, but with a bender. His plan is to sell the other two once we have this one done and sorted.

Here's the starting point: a warmoth swamp ash showcase body (re-routed for a strat pickup in the middle) , and a hipshot B-Bender mechanism.

Here's a mockup of what we hope to be a kickass guitar:

Now I have to confess that this is the first guitar that I've ever built for someone else. Because of that, I'm actually pretty nervous about the prospect! Small stuff that I would normally let pass I can't let happen. My worst fear is to F*ck something up. Because of this, I intend to check and double check everything as I go, as well as document the heck out of the build. If anything it will give Bill a story to tell! :headbang: